What are bioplastics?

Bioplastics are plastic materials characterized by their origin and/or environmental impact. In simple terms, a plastic is considered a bioplastic if it meets at least one of the following conditions: it is made entirely or partly from renewable raw materials (biological origin), or it is biodegradable (capable of breaking down through the action of microorganisms). Many bioplastics fulfill both characteristics, but not necessarily all. For instance, sugarcane-based polyethylene (Bio-PE) comes from plants and is bio-based but not biodegradable; conversely, there are biodegradable plastics made from petroleum, such as PBAT, which decompose but are not plant-derived.

In short, "bioplastic" is a broad term that encompasses a family of plastic materials derived from renewable and/or biodegradable sources.

The rise of bioplastics is a response to the search for more sustainable alternatives to conventional plastics. As environmental awareness increases, more companies are exploring these new materials to reduce fossil resource use and associated pollution. However, it’s important to understand that there is no single type of bioplastic but rather a range of polymers with different properties. In the following sections, we’ll examine how they are produced, the main types, their uses, and their advantages and disadvantages compared to traditional plastics.

How are bioplastics made?

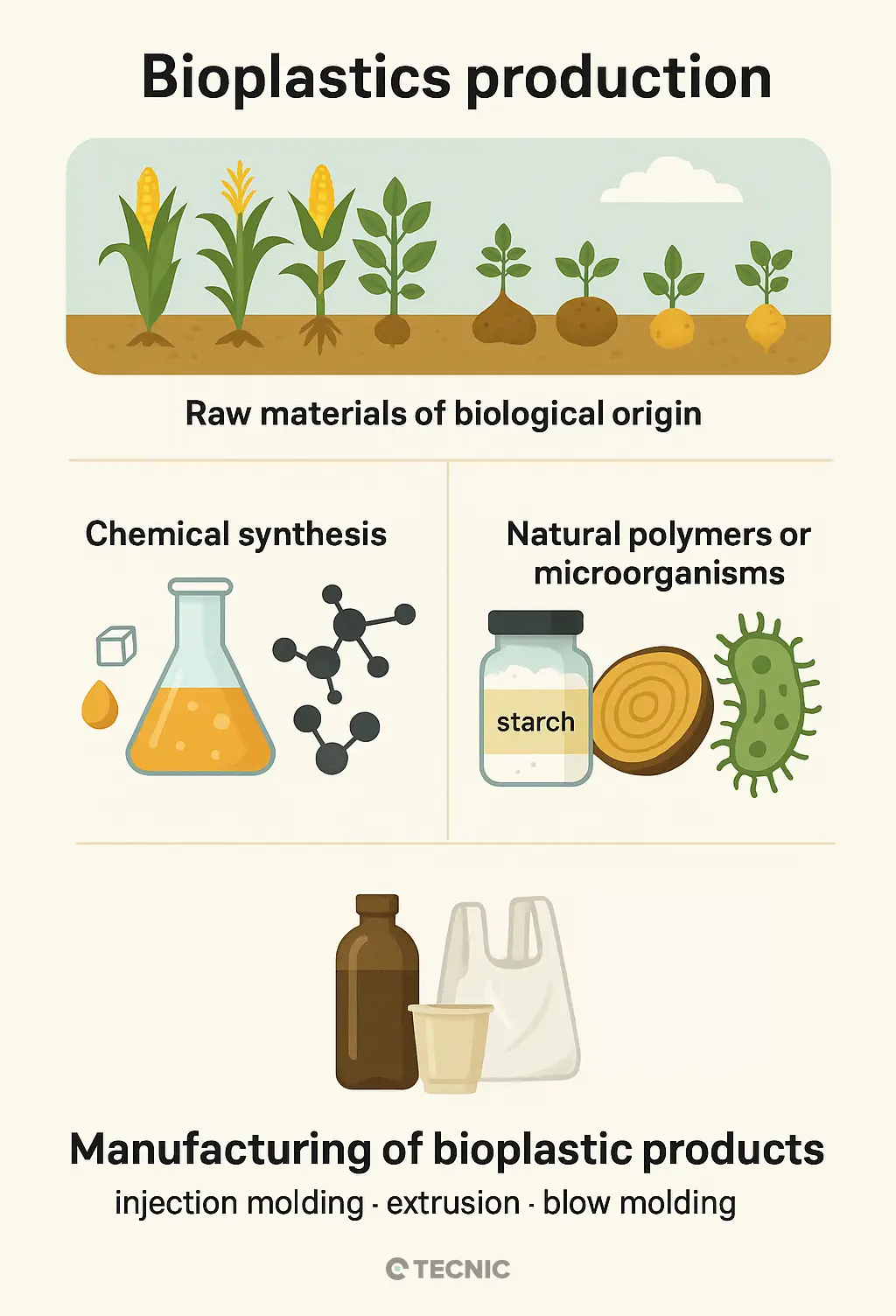

The production of bioplastics begins in the field, obtaining raw materials of biological origin. Currently, most come from carbohydrate-rich plants such as corn, sugarcane, potato or soy. These first-generation crops provide sugars, starch, or other compounds that serve as the basis for synthesizing polymers. They are highly efficient in yield, requiring relatively little land area to produce large quantities of raw material. Nonetheless, research is ongoing into second-generation sources (non-food), such as algae, agricultural waste or cellulose, to reduce reliance on food crops.

Once the plant biomass is obtained, there are two main routes to produce bioplastics:

- Chemical synthesis: In this process, sugars or vegetable oils are transformed into monomers via chemical reactions or microbial fermentation, and these monomers are then polymerized (linked into long chains) to form plastic. For example, corn or sugarcane sugar can be fermented to obtain lactic acid, which is then polymerized to produce PLA (polylactic acid). Similarly, ethanol from sugarcane can be converted into ethylene and then into bio-based polyethylene (Bio-PE). This method mimics that of conventional plastics (which polymerize petroleum derivatives) but uses biomolecules instead. The result is plastic resins that are molded into products with properties comparable to standard plastics.

- Use of natural polymers or microorganisms: Another route is to use polymers that already exist in nature. For example, corn or potato starch can be processed (gelatinized) and mixed with plasticizing additives to obtain a malleable material (starch plastic). Cellulose (from wood or cotton) is also used to make bioplastics like cellophane. Additionally, certain microorganisms (bacteria) can produce polymers inside their cells; such is the case of PHAs (polyhydroxyalkanoates), natural polyesters synthesized by bacteria fermenting sugars or lipids. These bacterial polymers are extracted and processed to obtain fully biodegradable plastics.

Once the polymers are obtained, the manufacturing of bioplastic items uses techniques similar to those of any plastic: injection molding, extrusion, blow molding, 3D printing, etc. In practice, the chain goes: cultivation of biomass → obtaining monomers or polymers → polymerization (if needed) → product manufacturing.

It’s worth noting that although the raw material source is different, bioplastic production still requires energy and chemical inputs; it involves industrial facilities and sometimes catalysts or solvents. Still, their carbon footprint tends to be lower than that of conventional plastics since part of the carbon they contain comes from CO₂ captured from the atmosphere by plants.

Main types of bioplastics

There are several types of bioplastics, each with its own characteristics and uses. They can be grouped into broad families with representative examples:

Bio-based plastics (derived from biomass): These are made from renewable raw materials such as plants or organic waste. They can be natural (polymers produced by organisms) or chemically synthesized from biomolecules. Examples:

- Polylactic acid (PLA): A polymer derived from sugars (corn, sugarcane). It is transparent and rigid, used in food packaging, bottles, disposable cups, cutlery, and plates. PLA is biodegradable under industrial composting conditions.

- Bio-based polyethylene (Bio-PE): Chemically identical to common plastic polyethylene, but produced from sugarcane ethanol instead of petroleum. Its properties are the same as conventional PE (flexible, resistant) and it is used for bags, packaging, and containers. It is not biodegradable, but being bio-based helps reduce the carbon footprint of its production.

Biodegradable/compostable plastics: These polymers are designed to naturally decompose under the action of microorganisms, ideally converting into water, CO₂, and biomass without leaving toxic residues. They can be of biological or fossil origin. Examples:

- Polyhydroxyalkanoates (PHA): A family of 100% biodegradable polyesters produced by bacteria that ferment organic matter. There are various types (PHB, PHBV, etc.), some of which are also biocompatible (suitable for medical use). PHAs can degrade even in marine environments and are used in biomedicine (sutures, implants), packaging, and single-use products.

- Polybutylene adipate terephthalate (PBAT): A synthetic, biodegradable (petroleum-derived) polymer that is very flexible. Often mixed with starch or PLA to produce trash bags and food wrappers. It fully degrades under composting conditions, releasing CO₂, water, and biomass.

- Thermoplastic starch polymer: Blends in which corn or potato starch is transformed into a plastic material. Used in compostable bags and items like disposable tableware. Starch alone is brittle, so it is often combined with PLA or PBAT to improve its properties. It is biodegradable and plant-derived.

Biocompatible polymers: These bioplastics are developed for applications in contact with living organisms, especially in medicine. For example, certain PHAs and copolymers such as PLA/PGA (polyglycolic acid) are used in medical implants, screws, stents, and surgical sutures that dissolve in the body after fulfilling their function. These materials must be bioabsorbable and non-reactive. Although their niche is more specific, they show how bioplastics can go beyond packaging and contribute to health innovations.

Applications of bioplastics

Bioplastics are already used in many sectors. Below is an overview of their main applications:

- Packaging and single-use products: This is the most widely adopted area. We find compostable shopping bags, food wraps and films, disposable tableware (plates, cutlery, straws), and even bottles made from bioplastics such as PLA or Bio-PET. For instance, some soda bottles are partially made with Bio-PET, and more supermarkets are offering biodegradable or compostable bags instead of conventional plastic ones. The key advantage is reducing persistent waste: these packages can degrade under suitable conditions instead of accumulating in landfills.

- Agriculture: In farming, bioplastics are used for biodegradable mulching films. Mulching is a plastic sheet placed over soil to retain moisture and prevent weeds; traditionally made of polyethylene, these films created a lot of waste upon removal. Today, there are mulching films made of biopolymers that degrade in the soil after harvest, eliminating the need to remove them and preventing plastic residues in the ground. Biodegradable seedling pots and trays are also used: they are planted directly with the seedling and decompose in the soil. These agricultural bioplastic products simplify operations and avoid plastic pollution in fields.

- Healthcare and medicine: As mentioned earlier, some bioplastics are ideal for medical applications. Absorbable sutures are made, which dissolve in the body after closing a wound, eliminating the need for surgical removal. Likewise, biodegradable orthopedic implants (nails, screws) are produced that support bones and then gradually degrade. In tissue engineering and drug delivery, polymers like PLA, PGA, or PHA are used to create matrices or capsules that the body can absorb. The key here is biocompatibility: these materials behave harmlessly inside the body and are eliminated naturally. Thanks to them, medicine can use devices that disappear once they fulfill their function, avoiding additional surgeries and reducing infection risks.

- Consumer products and textiles: Various companies have experimented with bioplastics in consumer goods. One example is textiles: PLA fibers exist that can be woven for clothing or upholstery, and biodegradable nonwoven fabrics are used in diapers, wet wipes, and disposable masks. During the COVID-19 pandemic, concern grew over the number of polypropylene masks being discarded; using biodegradable versions for such protective gear could significantly reduce their environmental impact. In fashion, there have even been demonstrations of garments made with biopolymer spray that solidifies into fabric and is completely compostable. While these are experimental developments, they illustrate the versatility of these materials.

- Electronics and automotive: Green electronics aim to reduce waste, and one of the challenges is electronic device waste. Some companies have started using bioplastics in phone cases, keyboards, mice, and other accessories. For example, phone cases with additives that make them compostable (once shredded) are already on the market. Research is also being done to incorporate biopolymers in circuit boards and internal components so that part of the device is easier to recycle or degrade at the end of its life cycle. In the automotive sector, some manufacturers use bio-based plastics in car interiors (like plant-based fibers in panels or bio-foam in seats) to reduce the environmental weight of vehicles. These components must meet high resistance standards, so their adoption is gradual.

- 3D printing: Additive manufacturing or 3D printing has become very popular, and one of its star materials is PLA. Being easy to print (low melting point, low shrinkage) and emitting fewer toxic odors than other plastics, PLA filament is widely used by makers and in educational settings. While PLA pieces are not biodegradable under household conditions, their renewable origin and absence of harmful gases during printing make them preferable for many non-industrial applications. Other biopolymers such as PLA-PHA blends are appearing to improve flexibility or heat resistance in 3D printing. This field shows another facet of bioplastics in technological innovation.

In general, bioplastic applications continue to expand as their properties improve and costs decrease. However, the packaging sector remains the largest consumer of bioplastics today (due to the urgency of replacing single-use plastics). Other sectors, such as agriculture or medicine, benefit from niches where biodegradability or biocompatibility offer a unique advantage over conventional plastics.

Bioplastic vs Plastic - Advantages and Disadvantages

| Aspect | Bioplastics | Conventional Plastics |

|---|---|---|

| Raw material origin | Renewable: made partly or entirely from plant biomass (corn, sugarcane, organic waste). Reduce dependency on limited fossil resources. | Non-renewable: made from petroleum or natural gas. Rely on finite fossil resources whose extraction generates environmental impacts. |

| Emissions and carbon footprint | Lower CO₂ footprint: during their life cycle, they may emit fewer greenhouse gases. Since the carbon comes from plants, their use can lead to net CO₂ savings compared to traditional plastics. | Additional fossil CO₂: production and consumption release carbon previously stored underground, contributing to climate change. Petrochemical manufacturing and incineration emit extra CO₂ into the atmosphere. |

| Biodegradability | Biodegradable (partly): many bioplastics can degrade biologically, but typically under specific conditions. Compostables break down in industrial composting facilities in months, without leaving microplastics. Note: not all bioplastics are biodegradable. | Not biodegradable: most conventional plastics do not decompose via microorganisms. They persist for decades or centuries in the environment, breaking into microplastics that pollute soil and oceans, harming fauna and ecosystems long-term. |

| Recycling and end of life | Complicated: bioplastics pose challenges in waste management. Compostables should not be mixed with recyclables (they contaminate the process). Some bio-based plastics can be recycled with their fossil-based equivalents, but in general, infrastructure for bioplastic recycling is limited. Mismanagement can hinder plastic recycling. | Established recycling: recycling chains exist for common plastics (PET, PE, PP), though effective recycling rates are low. Conventional plastics can be reprocessed several times, but in practice much ends up in landfills or incinerated. Since they are not biodegradable, their end-of-life often involves waste accumulation or CO₂ emissions. |

| Performance and properties | Improving: bioplastics have advanced in quality, offering properties similar to traditional plastics in many applications. However, some still show limitations, for example, PLA has a low melting point (~60°C) and can’t withstand high temperatures. Some biopolymers are less durable or more expensive to modify with additives. Innovation continues to improve durability and versatility. | High performance: conventional plastics have been optimized over decades. They offer a wide range of properties (flexibility, thermal and mechanical resistance) at low cost. Highly versatile: from ultra-strong engineering materials to ultra-thin films. In many critical applications (e.g., aerospace, medical), traditional polymers still dominate due to superior or more consistent performance. |

| Economic cost | Currently more expensive: bioplastic production is costlier due to the price of growing/processing biomass and less industrial scale. Traditional plastics are cheaper to mass-produce. However, as bioplastic production scales and technologies improve, prices are expected to drop. | Very cheap to produce: the petrochemical industry is highly developed, achieving extremely low costs per kilo. Historically, petroleum has been cheap as a raw material, making conventional plastics economical, driving their mass use. |

What are the problems associated with bioplastics?

Despite their potential benefits, bioplastics face several problems and challenges. Below are the main negative aspects and controversies:

- Conditional biodegradability: A common misconception is that a bioplastic item “disappears” quickly in nature. In reality, most bioplastics don’t degrade easily in natural environments. Many are only biodegradable in controlled settings like industrial composting plants with high temperature and humidity. For example, PLA needs around 60°C and specific microorganisms to compost; these conditions are absent in oceans or household landfills, so a PLA cup abandoned on the beach will remain intact for years, much like a regular plastic cup. Additionally, some bioplastics marketed as biodegradable may fragment into microplastics if improperly managed, contributing to microplastic pollution. In short, biodegradable does not mean harmless everywhere: infrastructure and proper conditions are required for them to fulfill their ecological promise.

- Insufficient waste management infrastructure: Closely related to the above is the issue of waste management. Current recycling and composting systems are not fully adapted to bioplastics. If a compostable bioplastic ends up in the plastic (yellow) bin by mistake, it can contaminate the recycling stream and ruin recovered materials. Conversely, if regular plastics are thrown into the organic or compost bin in the hope they will “degrade,” they will contaminate the compost. This confusion in waste separation is a challenge: the public often doesn’t know where each material should go, and compostable/recyclable symbols on packaging may be unfamiliar. Moreover, not all cities have industrial composting plants or separate organic waste collection; if these materials end up in regular landfills, their biodegradation potential is lost, and they may emit methane (a potent greenhouse gas) as they decompose anaerobically. In short, without a proper waste system, the ecological benefits of bioplastics go to waste.

- Competition with food and resource use: Producing bioplastics at scale requires farmland, water, and fertilizers for non-food crops. This raises concerns about diverting agricultural resources that could feed people. One study highlighted that intensive crop cultivation for bioplastics may cause fertilizer pollution and occupy land needed for food. However, currently the proportion of land used for bioplastics is very small (estimated at less than 0.02% of global agricultural land). Still, if demand grows significantly in the future, it will be essential to shift to second-generation feedstocks (waste, algae, etc.) to avoid worsening food security. Additionally, practices like deforestation to expand crops (e.g., more sugarcane or corn plantations) could negate the climate benefits of these materials. Environmental organizations warn that bioplastics are not free of environmental or social impacts: they may involve land grabbing, monocultures, and intensive agrochemical use, partly replicating the negative dynamics of industrial agriculture.

- They don’t eliminate the throwaway culture: Another criticism is that bioplastics, especially “eco-friendly” single-use items, may perpetuate the disposable mindset. It is estimated that 75% of bioplastics are used in single-use products (cups, wrappers, bags). If consumers believe that a cup or bag is “biodegradable and harmless,” they may care less about discarding it improperly, and it could still end up in nature or the sea. In that case, environmental harm occurs anyway. Greenpeace and other NGOs argue that promoting “bio” versions of disposables may be greenwashing, distracting from real solutions like reducing plastic consumption. Replacing a plastic fork with a compostable one doesn’t solve the waste crisis if we continue mass-producing and discarding them. The real solution is to reduce the production of unnecessary plastics, promote reuse, and improve waste management, rather than relying solely on changing the material.

- Cost and economic feasibility: Currently, producing bioplastics is more expensive than producing conventional plastics. This is due to the cost of raw materials (crops, sugars), conversion processes, and the fact that bioplastic plants operate at a smaller scale than traditional petrochemical facilities. For many applications, price is still a barrier: businesses and consumers often choose the cheaper option (conventional plastic) unless regulations or incentives are in place. Although prices may fall with economies of scale, there’s a risk that some bioplastics won’t be economically viable without support or sufficient market size. However, progress has been made: as carbon pricing rises or taxes on non-recycled plastic are introduced, bioplastics will become relatively more attractive. For now, their market share is small (less than 1% of all plastics produced), but it’s expected to grow in the coming years.

Conclusion

Bioplastics present both opportunities and challenges. They are not a magic solution to pollution on their own: if mismanaged, they can pollute almost as much as conventional plastics. Their industrial production also involves environmental impacts that must be minimized. However, when used appropriately, they can indeed reduce dependence on petroleum and pollution, for example, in applications where effective composting is possible or when they lead to net emission reductions.

Experts emphasize that the fight against plastic pollution should include bioplastics as part of a broader strategy, but should not rely solely on them. Promoting reduction, reuse, and better recycling practices remains essential to achieving a truly sustainable economy.

At TECNIC, we understand the complexity of implementing real sustainable solutions. That’s why we develop bioprocessing technologies that support efficient, scalable, and environmentally responsible production.

If you're exploring bioplastics or related biotech applications, feel free to contact our team of experts, we’ll be happy to help you evaluate the best path forward.

Frequently Asked Questions (FAQ)

Bioplastics are materials made from renewable sources like plants or microorganisms. Some are also biodegradable, but not all. They’re designed as alternatives to conventional fossil-based plastics.

Many bioplastics require industrial composting to degrade properly and can contaminate recycling streams if mismanaged.

Bioplastics are made from renewable materials like corn starch, sugarcane, potato, cellulose, or algae. Some are also produced by bacteria through fermentation.

Not all bioplastics are fully biodegradable. Some, like PHA or PLA, biodegrade under specific industrial conditions, while others, like Bio-PE, are not biodegradable at all.

They can reduce carbon footprint and fossil resource use, but their sustainability depends on proper production, disposal, and waste infrastructure.

References

AIMPLAS – Instituto Tecnológico del Plástico. (s. f.). Bioplásticos: tipos, aplicaciones y perspectivas.

European Bioplastics. (2023). Bioplastics market data 2023.

Greenpeace. (2020). Decepción biodegradable: el mito del bioplástico.

National Geographic. (2018). Are bioplastics really better for the environment?

Friends of the Earth Europe. (2020). The truth about bioplastics.

European Commission. (2018). A European strategy for plastics in a circular economy.